Long ODN synthesis and CBP purification

PRINCIPLE

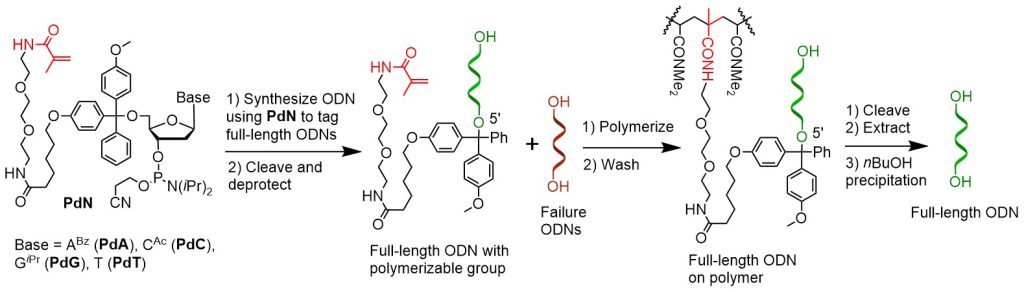

During oligodeoxynucleotide (ODN) synthesis, the failure sequences are capped with Ac2O and full-length sequences are tagged with a polymerizable nucleoside (PdN) phosphoramidite (Figure). After cleavage and deprotection, the crude contains the full-length sequences (the desired product) with a polymerizable group, failure sequences and small molecules. For purification, the full-length sequences are co-polymerized into a polyacrylamide gel. Failure sequences and small molecules are washed away. The product is cleaved and extracted, and precipitated with nBuOH.

MATERIALS (for purification of 1 μmol or less ODN)

Polymerizable dA amidite (PdA, MW 1156.3, 29 mg, 25 μmol; for sequences with a dA at 5′-end)

Polymerizable dC amidite (PdC, MW 1070.2, 27 mg, 25 μmol; for sequences with a dC at 5′-end)

Polymerizable dG amidite (PdG, MW 1138.3, 28 mg, 25 μmol; for sequences with a dG at 5′-end)

Polymerizable dT amidite (PdT, MW 1043.2, 26 mg, 25 μmol; for sequences with a dT at 5′-end)

Polymerization mix [PM, N,N-dimethylacrylamide, MW 99.1, d 0.96, 327 mg, 340 μl, 3.3 mmol; N,N’-methylenebis(acrylamide), MW 154.2, 17 mg, 110 μmol; polyacrylamide cross-linking ratio 20:1; sodium acrylate, MW 94.0, 3 mg, 33 µmol]

Polymerization initiator A (PIA, ammonium persulfate, MW 228.2, 10 mg, 44 μmol)

Polymerization initiator B (PIB, N,N,N’,N’-tetramethylethylenediamine, MW 116.2, d 0.78, 15.5 mg, 20 μl, 132 μmol)

PROTOCOL (more details in reference 1)

Synthesize ODN using PdN to tag full-length sequences

- Add 250 μl dry acetonitrile to PdN (0.1 M). Shake gently to dissolve.

- Conduct ODN synthesis on a synthesizer using Ac2O or Pac2O for capping.

- Incorporate the last nucleotide using PdN Coupling time should be 5-10 min. No deblocking in this cycle.

- Perform cleavage and deprotection as usual (UltraMild: conc. NH4OH, rt, 2 h; normal conditions: conc. NH4OH, 55 °C, 10-15 h; or conc. NH4OH/MeNH2 1/1, rt, ~3 h).

- Transfer ODN solution into a 1.5 ml centrifuge tube. Add ~0.1 mg K2CO3, and evaporate volatiles. The residue is the crude ODN with full-length sequences being tagged with PdN.

Polymerize full-length sequences

- Add 170 μl ddH2O to PM. Vortex and spin briefly.

- Add 190 μl ddH2O to PIA. Vortex and spin briefly.

- Add 190 μl ddH2O to PIB. Vortex and spin briefly.

- Add 50 μl ddH2O to crude ODN (or a portion of the crude). Vortex and spin briefly.

- Add 12 μl PM Vortex and spin briefly.

- Add PIA and PIB (5 μl), vortex (~1 sec) and spin (~5 sec) immediately.

- Cap the tube and let stand at rt for 1 h.

Wash away failure sequences and other impurities

- Transfer the gel to a 50 ml centrifuge tube and cut it into pieces (the pieces should be large enough for transfer).

- Add ~30 ml 20% NaOAc, shake gently at rt overnight.

- Remove supernatant.

- Add ~30 ml 5% Et3N, shake gently at rt overnight.

- Remove supernatant.

- Transfer the gel pieces onto the filter in a 2 ml centrifugal filter unit.

- Wash the gel with ddH2O (0.5 ml × 5).

Cleave and extract full-length sequences

- Add minimum 80% AcOH to cover the gel (~200 μl), wait for 3-5 min, spin.

- Dilute the filtrate with ddH2O (~800 µl) immediately.

- Repeat acid cleavage two times.

- Wash the gel with ddH2O (~250 µl × 3).

- Stop the bottom of the filtering unit with parafilm.

- Add ddH2O (~500 µl) to the gel, and gently shake the filtering unit at rt overnight.

- Combine the cleavage and washing filtrates.

- Evaporate to dryness. This gives the purified ODN. The following prescription step is optional (if precipitation is omitted, add ddH2O to the ODN and evaporate again to ensure residue acid is removed).

Precipitate (optional)

- Add 50 µl conc. NH4 Cap, vortex and spin.

- Add 450 μl n Close the cap.

- Vortex the tube for ~30 sec and then centrifuge at ~14.5k rpm (14.1k × g) for ~5 min.

- Remove the supernatant with a pipette, evaporate residue solvent. This gives the purified ODN.

REFERENCES AND NOTES

1. ChemRxiv [preprint] 2023 doi:10.26434/chemrxiv-2023-79qj3

2. Org Process Res Dev 2018 22 1282-1288 doi:10.1021/acs.oprd.8b00209

3. Green Chem 2016 18 1125-1136 doi:10.1039/c5gc01762a

4. Org Lett 2014 16 1290-1293 doi:10.1021/ol403426u

The steps for washing away failure sequences may not need to be as extensive as described. Smaller washing volume and shorter washing time may be sufficient, and it may be carried out in a centrifugal filtering unit.